Predetermined Overhead Rate Calculator & Formula Online Calculator Ultra

The predetermined overhead rate plays a pivotal role in financial decision-making processes. Hence, this predetermined overhead rate of 66.47 shall be applied to the pricing of the new product unearned revenue VXM. List all overhead costs incurred during a production period, such as rent, utilities, depreciation, and administrative expenses. The activity base needs to be a measure which will apply the manufacturing overhead to the products on a fair and impartial basis. Overhead expenses are generally fixed costs, meaning they’re incurred whether or not a factory produces a single item or a retail store sells a single product. Fixed costs would include building or office space rent, utilities, insurance, supplies, and maintenance and repair.

Plantwide Overhead Rate vs Departmental Rate

This means that if an actual overhead predetermined overhead rate rate is used by the business, the costs of products manufactured in summer will be higher than cost of goods manufactured in the winter. To tackle this problem predetermined overhead rates are used instead of actual overhead rates. The predetermined overhead rate computed above is known as single or plant-wide overhead rate which is mostly used by small companies.

How do you calculate predetermined overhead rate in accounting?

- The computation of the overhead cost per unit for all of the products is shown in Figure 6.4.

- A predetermined overhead rate is an allocation rate that is used to apply the estimated cost of manufacturing overhead to cost objects for a specific reporting period.

- (1) If wages are paid on piece rate basis, the time factor is totally ignored.

- It results in a more accurate representation of overhead costs for different production levels.

- The total manufacturing overhead cost will be variable overhead, and fixed overhead, which is the sum of 145,000 + 420,000 equals 565,000 total manufacturing overhead.

Predetermined overhead rates are used to determine the value of inventory, ensuring accurate financial reporting. Predetermined overhead rates serve as benchmarks for evaluating the efficiency of manufacturing processes and overhead control. For long-term contracts or projects, the percentage of completion method allocates overhead costs based on the project’s progress.

Calculating Direct Labor Hours

At a later stage, when the actual expenses are known, the difference between that allocated overhead and the actual expense is adjusted. If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too. That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty. When there Medical Billing Process is a big difference between the actual and estimated overheads, unexpected expenses will definitely be incurred. Also, profits will be affected when sales and production decisions are based on an inaccurate overhead rate. Calculating the Predetermined Overhead Rate (POR) is a critical step in cost accounting, particularly in the manufacturing sector.

Example 2: Cost per Hour

For example, the activity base for a production department might be the number of production hours. The activity base for an administrative department might be the number of employees. The price a business charges its customers is usually negotiated or decided based on the cost of manufacturing. This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit. Hence, one of the major advantages of predetermined overhead rate formula is that it is useful in price setting. Now ABC Co. can compare its estimated results with actual results to evaluate how it has performed.

- Predetermined overhead rates are essential to understand for ecommerce businesses as they can be used to price products or services more accurately.

- This predetermined overhead rate can also be used to help the marketing agency estimate its margin on a project.

- If these estimates are not accurate, they can end up causing a lot of problems for the business specially if decisions are based on the rates, such as pricing decisions.

- Since overhead costs cannot be easily traced to individual products like direct material or labor costs, overhead rates help to allocate a fair share of these costs based on the activity of making the product.

- As someone who has spent years working in accounting and financial management, I know how confusing overhead allocation can be for beginners.

- The agency knows from its predetermined overhead rate that it will incur $200 in overhead costs for the project.

Setting pricing

As you have learned, the overhead needs to be allocated to the manufactured product in a systematic and rational manner. This allocation process depends on the use of a cost driver, which drives the production activity’s cost. Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs. If a job is in work in process and has recorded actual direct labor hours of 600 during an accounting period then the predetermined overhead applied to the job is calculated as follows. One of the advantages of predetermined overhead rate is that businesses can use it to help with closing their books more quickly. This is because using this rate allows them to avoid compiling actual overhead costs as part of their closing process.

Problems with Predetermined Overhead Rates

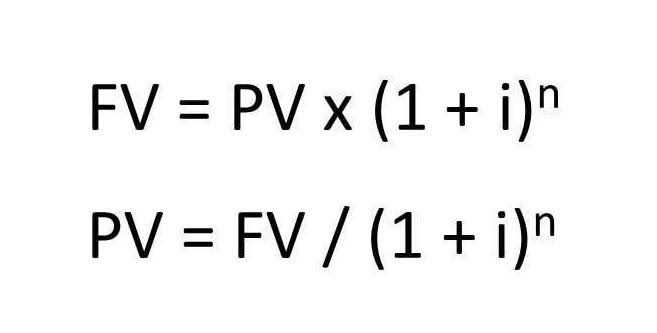

It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount). The formula for calculating Predetermined Overhead Rate is represented as follows. By knowing the total overhead costs for a period in advance, businesses can plan for the necessary cash flow to cover these costs.

The ABC method involves identifying and assigning overhead costs to specific activities that are required to produce goods or services. It then divides the total overhead costs for each activity by the corresponding activity volume to derive the predetermined overhead rate for that activity. The ABC method is more complex than the traditional method but can provide more accurate and granular overhead cost allocation. The traditional method involves dividing the total estimated overhead costs by the total estimated activity base for a given period. This is a straightforward approach but can be less accurate if the overhead costs and activity levels do not have a consistent relationship or if the estimates are not reliable.